- Tel: 0086-21-35324116

- E-mail: sales@shenglincooling.com

Introduction

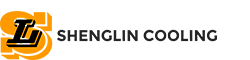

Air-liquid heat exchanger type liquid-cooled CDU directly utilizes air to cool the circulating medium in the liquid-cooled system, in which the air side contains high-efficiency copper tube and aluminum fin heat exchanger, EC fan composition; the secondary side contains variable frequency circulating pump, temperature sensors, pressure sensors, filters, flow meters (optional). The product adopts factory pre-installation and commissioning, rack mounting and use, external interface for quick release chuck (standard), quick plug connector (optional) and terminal structure, simple and convenient.

Performance range

· Heat transfer quantity:8~16kW

Product characteristics

(1)Precise control

· Liquid cooling intelligent control system, featuring temperature monitoring, PTpressure monitoring, flow detection, water quality monitoring, and anti-condensation control, with the highest temperature control accuracy reaching +0.5℃

(2)High energy efficiency

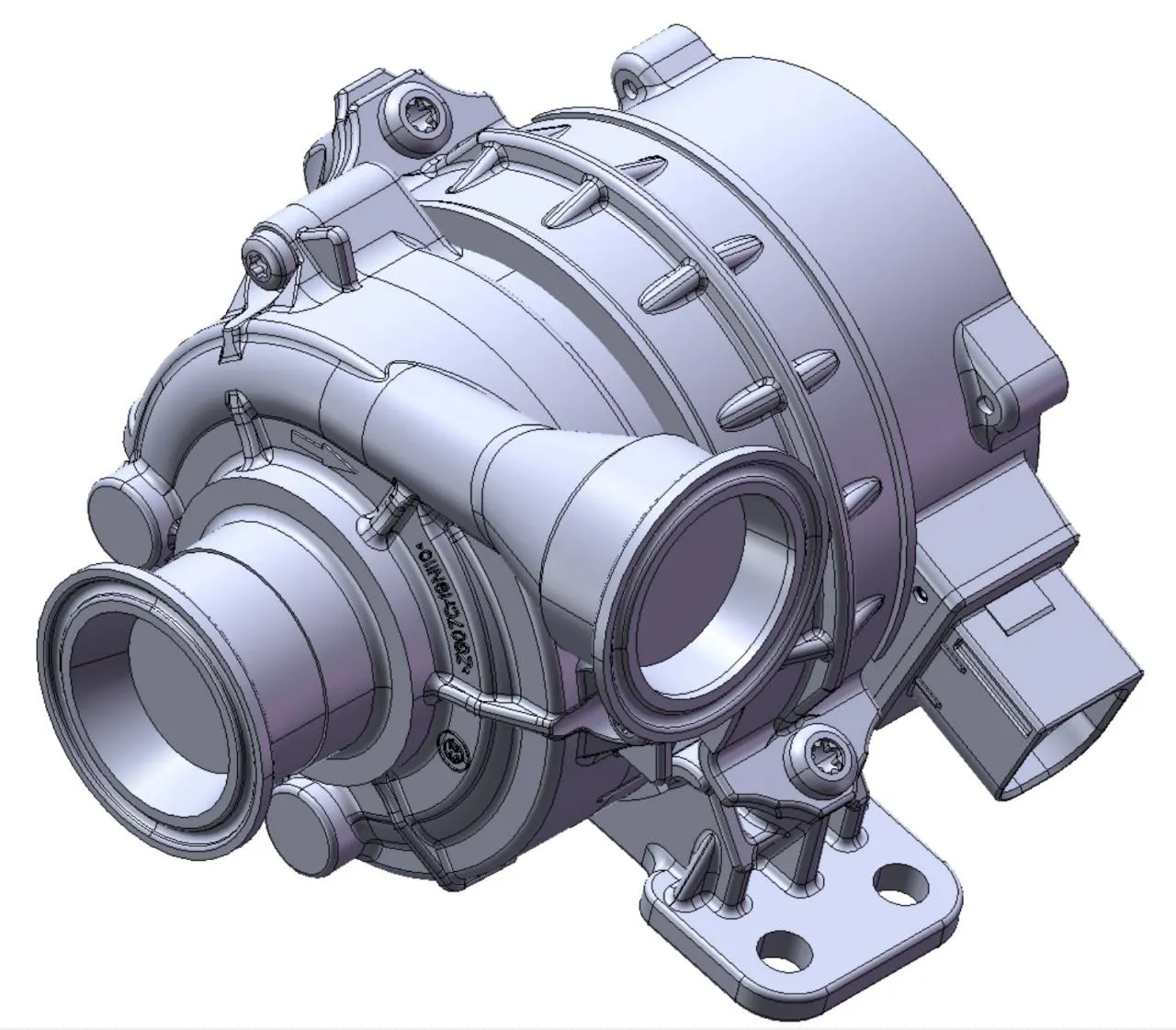

· Copper tube/stainless steel tube finned heat exchanger: Highly efficient heat exchange

(3)High compatibility

(4)High reliability

TECHNICAL PARAMETER(1)

| Model | CDU17AC1DP | CDU20AC1DP | CDU16AC3DP | CDU10AC1SP | |

| Material code | 80020004 | 80020005 | 80020006 | 80020007 | |

| Power supply | 100-240VAC, 50/60Hz | ||||

| Performance parameters of the unit | |||||

|

Return air at 25℃, supply and return liquid at 40/50℃ |

Heat exchange capacity-kW |

19.1 | 21.4 | 20.1 | 11.0 |

| Flow rate- m3/h | 2.07 | 1.83 | 1.74 | 0.94 | |

|

Rated power of the unit-kW |

2.9 | 2.3 | 1.8 | 1.9 | |

|

Return air at 26℃, supply and return liquid at 40/50℃ |

Heat exchange capacity-kW |

18.1 | 20.1 | 19 | 10.4 |

| Flow rate- m3/h | 1.96 | 1.73 | 1.65 | 0.89 | |

|

Rated power of the unit-kW |

2.9 | 2.3 | 1.8 | 1.9 | |

|

Return air at 27℃, supply and return liquid at 40/50℃ |

Heat exchange capacity-kW |

17.0 | 18.8 | 17.9 | 9.75 |

| Flow rate- m3/h | 1.80 | 1.62 | 1.45 | 0.85 | |

|

Rated power of the unit-kW |

2.9 | 2.3 | 1.8 | 1.9 | |

|

Return air at 28℃, supply and return liquid at 40/50℃ |

Heat exchange capacity-kW |

16.0 | 17.6 | 16.8 | 9.15 |

| Flow rate- m3/h | 1.73 | 1.51 | 1.45 | 0.79 | |

|

Rated power of the unit-kW |

2.9 | 2.3 | 1.8 | 1.9 | |

|

Return air at 29℃, supply and return liquid at 40/50℃ |

Heat exchange capacity-kW |

14.9 | 16.3 | 15.7 | 8.55 |

| Flow rate- m3/h | 1.62 | 1.39 | 1.35 | 0.74 | |

|

Rated power of the unit-kW |

2.9 | 2.3 | 1.8 | 1.9 | |

|

Return air at 30℃, supply and return liquid at 40/50℃ |

Heat exchange capacity-kW |

13.8 | 15.0 | 14.6 | 7.95 |

| Flow rate- m3/h | 1.5 | 1.29 | 1.26 | 0.69 | |

|

Rated power of the unit-kW |

2.9 | 2.3 | 1.8 | 1.9 | |

| The secondary medium | deionized water, ethylene glycol solution and propylene glycol solution | ||||

| Installation method | Rack-mounted | ||||

| Performance parameters of the circulating pump | |||||

| The number of circulating pumps | 2 | 2 | 2 | 1 | |

| The rated power of the circulating pump | 0.40 | 0.40 | 0.40 | 0.40 | |

| Fan performance parameters | |||||

| Circulating air volume | 4800 | 5000 | 4000 | 2000 | |

| The number of fans | 4(3+1) | 6(5+1) | 4 | 2 | |

| Performance parameters of heat exchanger | |||||

| Number of heat exchangers | 1 | 1 | 1 | 1 | |

| The number of rows of the heat exchanger | 4 | 4 | 4 | 4 | |

| Size and specification of the connecting pipe | |||||

| Pipe connection specifications | DN20 | DN20 | DN20 | DN20 | |

| Interface type A | Chuck | Chuck | Chuck | Chuck | |

| Interface type B |

Quick connection |

Quick connection | Quick connection | Quick connection | |

| Unit size and weight | |||||

| Unit width -mm | 502 | 500 | 500 | 500 | |

| Unit depth -mm | 1062 | 1013 | 890 | 957 | |

| Unit height-mm | 742(16SU) | 800(18U) | 444(10U) | 444(10U) | |

| Weight -kg | 109 | 125 | 70 | 70 | |

| Recommended specifications for circuit breakers and cables | |||||

|

Recommended circuit breaker specification -A |

16 | 16 | 16 | 16 | |

| Recommended cable specifications | 3*2.5 | 3*2.5 | 3*2.5 | 3*2.5 | |

| Model | CDU009AC1SM | CDU016AC1SM | CDU016AC3DM | |

| Material code | 80020001 | 80020002 | 80020003 | |

| Power supply | 100-240VAC, 50/60Hz | |||

| Performance parameters of the unit | ||||

| Return air at 27℃, supply and return liquid at 40/50℃ | heat exchange capacity -kW | 8.7 | 16.7 | 16.7 |

| Flow rate -m³/h | 0.75 | 1.43 | 1.43 | |

| Rated power of the unit-kW | 0.68 | 1.17 | 1.17 | |

| Return air at 28℃, supply and return liquid at 40/50℃ | heat exchange capacity -kW | 7.4 | 14.2 | 14.2 |

| Flow rate -m³/h | 1.27 | 2.44 | 2.44 | |

| Rated power of the unit-kW | 0.68 | 1.17 | 1.17 | |

| Return air at 28℃, supply and return liquid at 40/50℃ | heat exchange capacity -kW | 8.1 | 15.5 | 15.5 |

| Flow rate -m³/h | 0.7 | 1.33 | 1.33 | |

| Rated power of the unit-kW | 0.68 | 1.17 | 1.17 | |

| The secondary medium | deionized water, ethylene glycol solution and propylene glycol solution | |||

| Installation method | Rack-mounted | |||

| Performance parameters of the circulating pump | ||||

| The number of circulating pumps | 1 | 1 | 1+1 | |

| The rated power of the circulating pump | 0.22 | 0.3 | 0.3 | |

| Fan performance parameters | ||||

| Circulating air volume | 2000 | 4000 | 4000 | |

| The number of fans | 2 | 4 | 4 | |

| Performance parameters of heat exchanger | ||||

| Number of heat exchangers | 1 | 1 | 1 | |

| The number of rows of the heat exchanger | 4 | 4 | 4 | |

| Size and specification of the connecting pipe | ||||

| Pipe connection specifications | DN15 | DN20 | DN20 | |

| Interface type A | Chuck | Chuck | Chuck | |

| Interface type B | Quick connection | Quick connection | Quick connection | |

| Unit size and weight | ||||

| Unit width -mm | 440 | 440 | 440 | |

| Unit depth -mm | 850 | 850 | 850 | |

| Unit height-mm | 222(5U) | 444(10U) | 444(10U) | |

| Weight -kg | 35 | 50 | 50 | |

| Recommended specifications for circuit breakers and cables | ||||

| Recommended circuit breaker specification -A | 16 | 16 | 16 | |

| Recommended cable specifications | 3*2.5 | 3*2.5 | 3*2.5 | |

Note: Customized products for other working conditions are available.

(1)High-power density datacenters: In scenarios such as high-performance computing (HPC), cloud computing, and Al training, the server density is relatively high, generating a huge amount of heat. The wind liquid CDU can quickly remove heat through liquid cooling technology, ensuring that the operating temperature of the equipment remains within a safe range.

(2)Prefabricated and modular data centers: In prefabricated or modular deployments, space is limited and thermal loads are concentrated. The compact design and efficient cooling capacity of the wind-liquid CDU make it an ideal choice.

(3)Green energy and energy-saving upgrades: As enterprises place greater emphasis on environmental protection and energy conservation, wind liquid CDU helps data centers achieve low-carbon operation goals by reducing power consumption and enhancing cooling efficiency.

(4)Applied to micro and space-constrained data centers: Modular design ADAPTS to heterogeneous computer room layouts, no infrastructure modification is required, and it supports rapid deployment beside racks.

1、CORE COMPONENTS

|

EC fans

|

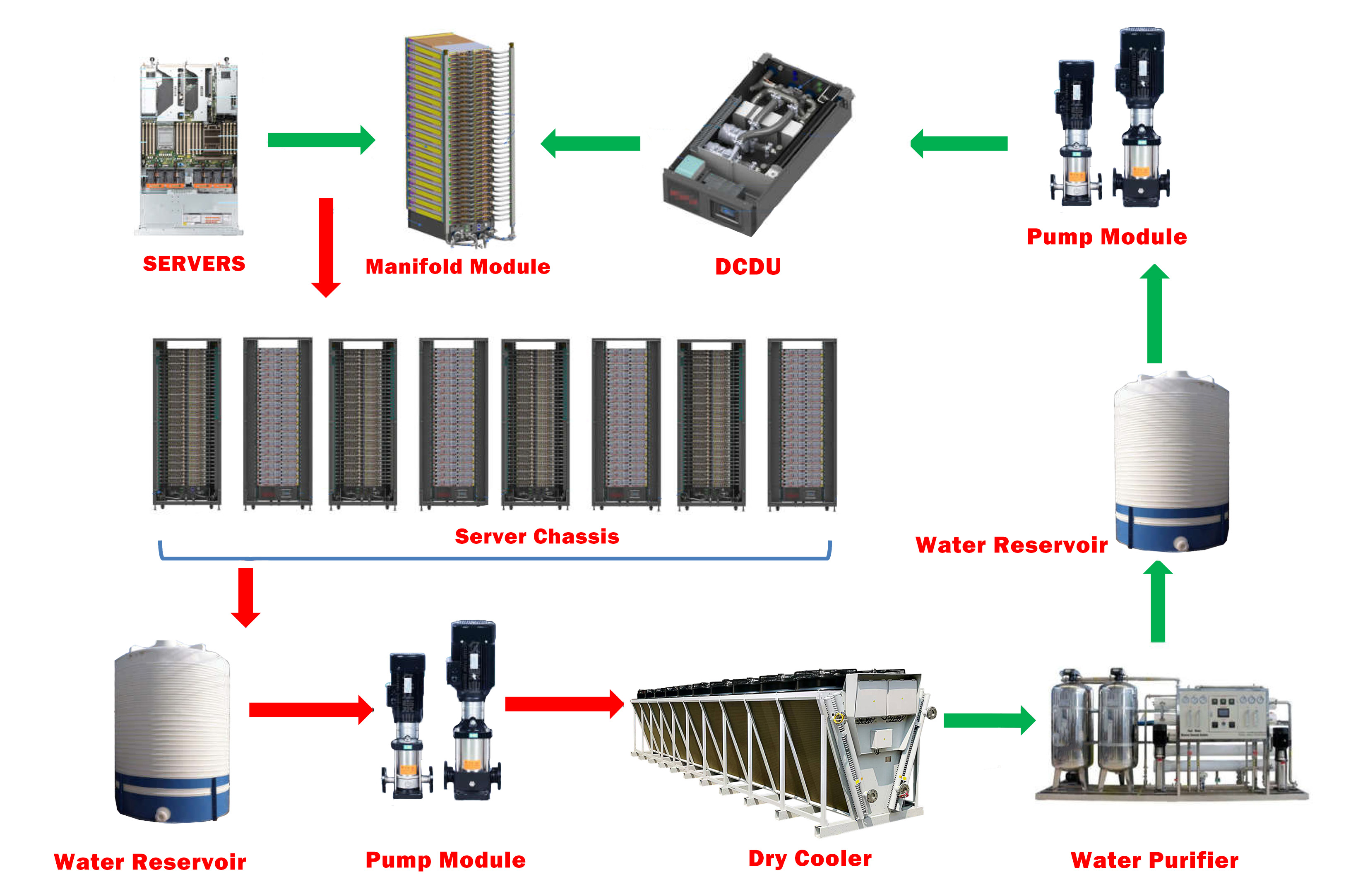

High-efficiency variable frequency pump

|

|

|

|

Finned heat exchanger

|

Flowmeter

|

|

|

|

Temperature sensor

|

Pressure sensor

|

|

|

2、Water quality monitoring sensor(Select accessories)

| Select accessories | function |

| Backup of temperature and pressure sensors | Participate in the backup of control points to ensure system stability |

| Conductivity sensor | Monitor the electrical conductivity of the liquid in the pipeline in real time to determine the purity or composition changes of the liquid |

| PH sensor | Monitor the pH level of the coolant in the pipeline in real time to prevent excessive acidity from accelerating metal corrosion and excessive alkalinity from causing scaling |

| Total hardness sensor | Monitor the total hardness of the coolant in the pipeline in real time, that is, the total concentration of calcium and magnesium ions in the water, to soften the water in time for treatment and prevent scaling |

| Turbidity sensor | Monitor the turbidity of the liquid in the pipeline in real time to reflect the content of suspended particulate matter in the liquid |