- Tel: 0086-21-35324116

- E-mail: sales@shenglincooling.com

Introduction

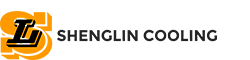

Liquid-to-Liquid Coolant Distribution Unit (CDU) , Installed in the cabinet. It is a core cooling device designed for high-density heat dissipation requirements, achieving efficient heat exchange through liquid circulation. Its core function is to absorb the heat of IT equipment through the coolant on the secondary side, and then transfer the heat to the outside through the external cooling system on the primary side (such as chilled water, natural cold sources, etc.), thereby maintaining the operation of IT equipment within a safe temperature range.

Performance Range

· Heat Transfer Capacity:350~1500kW

Product characteristics

(1)Precise control

· Liquid cooling intelligent control system, featuring temperature monitoring, PTpressure monitoring, flow detection, water quality monitoring, and anti-condensation control, with the highest temperature control accuracy reaching +0.5℃

(2)High energy efficiency

(3)High compatibility

(4)High reliability

|

Indoor unit model

|

CDU100WC3DP

|

CDU080WC1DP

|

CDU050WC1DP

|

CDU030WC3DP

|

CDU030WC1SM

|

|

code

|

80030008

|

80030001

|

80030005

|

80030002

|

80030003

|

|

Power supply

|

100-240VAC,50/60Hz

|

||||

|

Performance parameters of the unit

|

|||||

|

Primary side operating condition

|

35℃/45℃

|

35℃/45℃

|

35℃/40℃

|

35℃/42℃

|

35℃/42℃

|

|

Secondary side operating condition

|

55℃/40℃

|

50℃/40℃

|

50℃/40℃

|

47℃/40℃

|

47℃/40℃

|

|

Heat exchange

capacity-kW

|

105.60

|

80.00

|

50.50

|

32.20

|

32.20

|

|

Primary side flow rate-m³/h

|

9.08

|

6.88

|

8.68

|

3.96

|

3.96

|

|

Secondary side flow rate-m³/h

|

6.05

|

6.88

|

4.34

|

3.96

|

3.96

|

|

The rated power of the unit is-kW

|

0.95

|

2.00

|

0.54

|

0.54

|

0.54

|

|

Primary

side medium

|

Softened water, ethylene glycol solution

|

||||

|

Secondary side medium

|

deionized water, ethylene glycol solution and propylene glycol solution

|

||||

|

Performance parameters of the circulating pump

|

|||||

|

The number of circulating pumps

|

1+1 | 2 | 1+1 | 1+1 | 1+1 |

|

The rated power of the circulating pump

-kW |

0.75

|

1.50

|

0.40

|

0.40

|

0.40

|

|

Available head -m

|

10

|

10

|

10

|

10

|

10

|

|

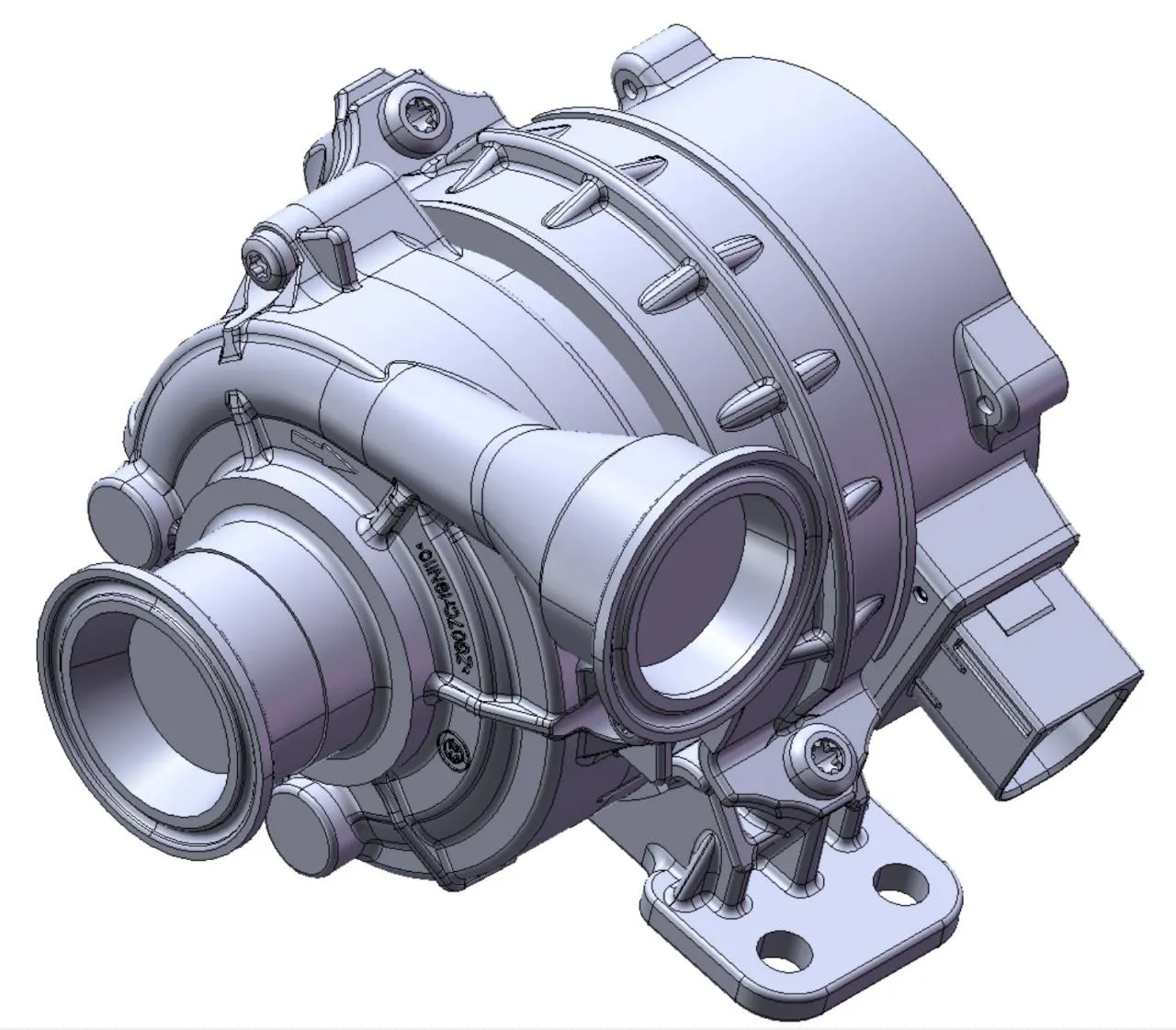

Performance parameters of heat exchanger

|

|||||

|

Number of heat

exchangers

|

1

|

1

|

1

|

1

|

1

|

|

Size and specification of the connecting pipe

|

|||||

|

Primary side

pipeline

|

DN20

|

DN25

|

DN20

|

DN20

|

DN20

|

|

Secondary side

pipeline

|

DN20

|

DN32

|

DN20

|

DN20

|

DN20

|

|

Interface type

|

Chuck

|

||||

|

Optional

interface type

|

Quick connection

|

||||

|

Unit size and weight

|

|||||

|

Unit width -mm

|

447

|

440

|

440

|

440

|

500

|

|

Unit depth -mm

|

1057

|

914 | 890 | 890 | 860 |

|

Unit height-mm

|

180(4U)

|

402(9U)

|

180(4U)

|

180(4U) | 180(4U) |

|

Weight -kg

|

50 | 70 | 45 | 45 | 45 |

|

Recommended specifications for circuit breakers and cables

|

|||||

|

Recommended

circuit breaker

specification -A

|

16 | 16 | 16 | 16 | 16 |

|

Recommended

cable specifications

-mm2 |

3*2.5 | 3*2.5 | 3*2.5 | 3*2.5 | 3*2.5 |

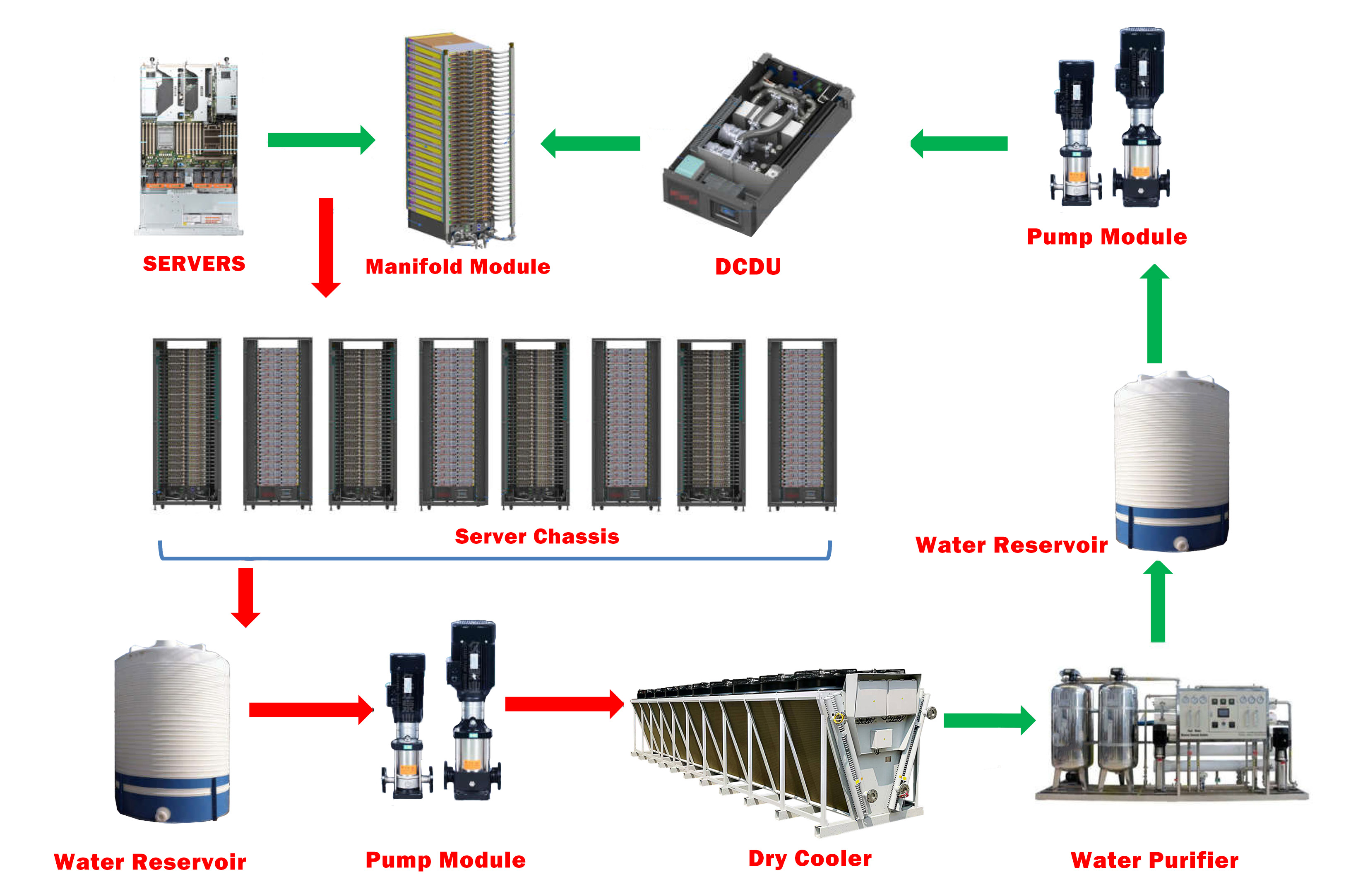

1、CORE COMPONENTS

|

High-efficiency variable frequency pump

|

|

|

|

|

Plate heat exchanger

|

Flowmeter

|

|

|

|

Temperature sensor

|

Pressure sensor

|

|

|

2、Water quality monitoring sensor(Select accessories)

| Select accessories | function |

| Backup of temperature and pressure sensors | Participate in the backup of control points to ensure system stability |

| Conductivity sensor | Monitor the electrical conductivity of the liquid in the pipeline in real time to determine the purity or composition changes of the liquid |

| PH sensor | Monitor the pH level of the coolant in the pipeline in real time to prevent excessive acidity from accelerating metal corrosion and excessive alkalinity from causing scaling |

| Total hardness sensor | Monitor the total hardness of the coolant in the pipeline in real time, that is, the total concentration of calcium and magnesium ions in the water, to soften the water in time for treatment and prevent scaling |

| Turbidity sensor | Monitor the turbidity of the liquid in the pipeline in real time to reflect the content of suspended particulate matter in the liquid |